Can You Lay an Air Compressor On Its Side? Compressor Types You Can Lay Down!

TheToolGeeks.com is a participant in the Amazon Services LLC Associates Program and other affiliate advertising programs. We may earn from qualifying purchases. (Learn More).

Air compressors are very valuable both for general housework and industrial work. They are sometimes bulky, which makes storing and transporting difficult. There are different positions you can put your air compressor in to transport them. One of the positions is laying the compressor on its side. But, Can you lay an air compressor on its side?

Most technicians and engineers ask this question. Of course, you also have this question in mind; that’s why you’ve landed on this same page. Don’t worry; we’re going to answer everything.

There is a general rule for compressors never lay them down unless it is new (which means there is no oil or moisture in them).

Reading this article will help you know can you lay down or put your compressor in sideway. We’ll discuss how air compressors work and how to maintain and service them to keep them working for you!

Learn How Air Compressor Works

In an air compressor, the air gets forced into a container, and it gets into the container where it gets built up, like an open ballon. In a compressor, electrical energy is converted into kinetic energy through which they get powered, like a combustion engine. After, the pressured air uses pneumatic tools: nailers, guns, etc.

Oil-Lubricated Air Compressor Vs Oil-Free Air Compressor

Regular maintenance is among many differences beyond oil presence and absence in an oil-lubricated and oil-free compressor. Oil-free air compressors do not need maintenance, while oil-lubricated ones need regular.

You need to change the oil in an oil-lubricated compressor once. Also, it needs more filtration: separators and coalescing to help remove oil. But they are loud. However, oil-free needs more repair working and does not last long.

Can You Lay an Air Compressor on Its Side?

You may consider laying down your compressor based on new or old because a new one will not have any oil or moisture. Also, you may consider an oil-lubricated or oil-less feature, but the used compressor has build-up moisture you need to consider.

What About Oil-Lubricated Air Compressor? Can you Lay it Down too?

Never lay down an oil-lubricated compressor because it is not only oil that can lead to the other parts of the compressor where it should not be but will contaminate the parts. Also, oil and other particles will accumulate at the bottom and ruin the working and performance of the compressor.

What happens if you lay an Oil-Lubricated air compressor on its side?

Laying down an air compressor is never a good idea, especially an oil-lubricated one. Why? Because there are chances of oil getting into the check valve near the airline pump, this will end in compressor breakdown, stress, and lousy performance.

Can I lay Down my Oil-Free Air Compressor?

Oil-free compressors have no oil, so there is no issue in lying down it down. However, this is never a good idea to lay down compressors because, over-time particles and moisture can accumulate at the bottom of the unit.

Air intake filters prevent dust from entering the unit, but it will get dirty and enter the air tank over time. Lying the compressor down will let the sludge into the check valve and not let it work properly.

What Happens if you Lay an Oil-Free Air Compressor on Its Side?

Oil-free compressors have no oil and make it a little easier than you can consider laying it down. However, you should always put a compressor on the right way because even in the oil-free compressor, moisture can accumulate and affect the unit and its performance.

Laying Down Old Vs. New Air Compressor

New air compressors (totally new and never used) have no oil, water, or dirt particles. So you can lay them down. Without oil or fluid, there is no reason not to lay the unit down, and you can lay it down for storage and transport.

Further, never lay down a used or old air compressor because moisture can get sludge in the button of the unit and can cause damage to the compressor. Nowadays, some compressors come with oil. Ensure the unit has no oil before laying it down, and avoid laying the unit down.

Can You Lay Down a Vertical Air Compressor On Its Side?

The orientation of laying down an air compressor more than depending on vertical or horizontal depends on the oil-lubrication and oilless feature. Why? Because even if your compressor is vertical but is oil-free. You can lay it down, but you cannot do this will an oil-lubricated compressor. However, always avoid laying down your compressor in any position.

Can you lay a 60-gallon air compressor on its side?

First, determine whether your compressor is oil-free or oil-lubricated, and then decide. However, 60-8- Gallon compressors come with oil installed. So, avoid laying it down or putting it on the side because it can accumulate moisture even if it’s new. Even if you do not put it down on the side, it can cause moisture or oil to get into other unit parts.

How to Transport an Air Compressor a Right Way?

While transporting, make sure to do these steps:

- Check oil/ empty.

- Check tank of compressor/ ensure it’s empty.

- Use a trailer and use helping hands.

- Secure it properly.

- You can make it apart (it will help keep it upright).

Can you transport an oilless air compressor on its side?

The oil-free compressor has no issue with oil mishaps. So it is completely fine to transport your oil-free compressor on its side. However, do not keep it inside position longer because it can damage the drain valve or can lead to accumulating particles, and the check valve will prevent it from working.

How to Lift an Air Compressor?

You can lift your compressor by many methods: you can attach a string with the compressor and motor and then lift it from above, not from the bottom. The concrete slab can also be bolted down with anchor wedges and vibration pads. Mark two holes in concrete and drill them. Move the compressor back into place. While installing anchor wedges loosely, tip it back enough so each one can slip from the pad at a time, and then snug the anchor wedges down.

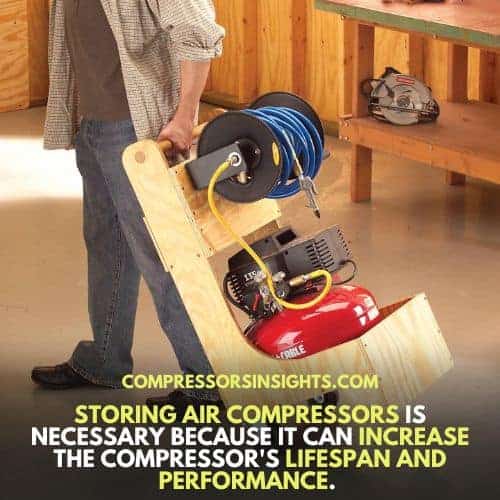

How to Store an Air Compressor a Right Way?

Storing air compressors is necessary because it can affect the compressor’s lifespan and its performance. There are a few steps to take while keeping the unit.

- Choose a location to store where there is no sunlight and a platform where moisture is unreachable. After turning off the compressor, unplug it.

- Enusre to release all the pressure ( if you are storing it for a long time), and de attach the pneumatic tools and hoses.

- Drain the compressor tank by removing air from the compressor tank and keep it open until it gets dry and empty the valves to dry the moisture (it can cause rusting).

- Store it in a bag or box.

How to Maintain Your Air Compressor For a Long-Term Use?

Maintaining the compressor not makes its performance better and more efficient but also longers the lifespan of the unit. But you need to properly keep it, and there are a few tips: that can help you retain the compressor easily.

Reading manual

There are a lot of problems that users can easily. Resolve just by reading the manuals of the compressor. It states proper solutions to issues and steps.

Observing your compressor helps you catch any abnormal conditions. Observe sounds, reading, heating, and vibration.

Check nuts and bolts

Nuts and bolts of the compressor get loose after daily usage, and it also happens because of the constant vibration while running the unit. Ensure every nuts and bolt is tight before using the unit.

Intake valve cleaning

For the air compressor to function appropriately, clean its intake valve. The particles and other elements get stuck in the vents. Ensure to clean it after every use, in dusty areas ( construction, woodcutting). It is more important to clean them.

Hose Checking

Hoses are most valuable among other parts and help transfer air from the unit to the pneumatic tools. It needs to be solid and tight( not too much). Ensure there is no leakage in the hose regularly.

Air filters changing/ cleaning

Filters inside the compressors collect particles from the air and bear heavy loads. If there are no particles, the dust and impurities will get into the compressor and affect its efficiency, damaging the attached pneumatic tools. Make sure to clean or change if damaged the filters of the unit.

Ensure no moisture

Moisture accumulates in the compressor in the form of condensate. There is a moisture tank that sucks the water from the air, and it helps the air to remain dry and pure. When you do not empty the moisture tank, eventually, it moves towards the other parts of the unit, causing damage, smell, and impurities in the team.

Cleaning fuel tank

Fuel tanks require more maintenance fuel particles can accumulate in the tank and become toxic and rust. The tank needs to be cleaned once in a while to prevent it from becoming poisonous. Drain the fuel tank, clean it and then dry it before using it again.

Check the shutoff system

Some compressors shut down whenever there is overheating or a short circuit. For their well-being, they need to shut down. The larger machines face more costs when they get damaged. This feature activates upon overheating or pressure, which shuts off the unit and saves it from big fail. In humid working conditions, this safety feature can fail. Ensure it’s working correctly before starting your work.

Oil changing/Checking

As you know, not all compressor needs oil. The oil-lubricated compressor needs oil changing, cleaning, and maintenance. It needs to be fresh to let parts run smoothly, and oil loses its viscosity and does not provide proper smoothness to parts.

Lack of lubrication causes stress and results in the breakdown of the unit. In the cold, moisture can get into the oil, causing it to become sludgy. Change your compressor oil after every one or two cycles.

Checking oil/air separator

Oil-lubricated compressors need oil to function. In compressors, oil gets extracted through the air before leaving the unit. It helps in lubricating the compressor and keeping the air dry. Suppose the oil separator does not work correctly. It will enter the air. Oil presence in the tool can affect the working of the tool. Ensure to clean or change the filter to keep it safe.

Conclusion

Compressors are great units and take less space, especially vertical compressors but can you lay an air compressor on its side? Will it affect its working or performance? Other than taking more space, there will be additional wear and stress on parts of the unit and causing overheating.

Maintenance of an oil-lubricated air compressor is necessary, and you can maintain any compressor by checking its oil, filters, oil separators, nuts, bolts, shutoff system, moisture, and fuel tank. Ensure to keep your compressor clean!!

FAQ’s

Can you mount a compressor sideways?

Mounting an air compressor sideways leads to stress on components of the unit and not only causes additional wear but heat dissipation and overheating issues. Mount the compressor on the right way.

Is a vertical or horizontal air compressor better?

When you compare vertical and horizontal air compressor working capacity, other than if features of the compressor are different, there is no difference in them. Compressor performance and storage capacity are the same. However, a vertical compressor takes less space relative to a horizontal one and will allow you to free more space.

Will an air compressor work upside down?

Putting an air compressor upside down can lead to stress on the parts of the compressor, and it not only causes more wear and overheating issues and heat dissipation issues. Pressure on the unit’s components eventually shortens the life of the unit.

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.