Can I Use Motor Oil in My Air Compressor? 2 Air Compressor Oil Substitutes!

TheToolGeeks.com is a participant in the Amazon Services LLC Associates Program and other affiliate advertising programs. We may earn from qualifying purchases. (Learn More).

Oil is one of the most necessary thing for machinery like engine, injection molding, and air compressors. And, why not? After all, it makes sure the machinery keep running smoothly.

When we talk about oil, motor oil is one of most common oil in the market. But, there is a question that is roaming around: Can I use motor oil in my air compressor? That can be a tricky question with a lot of different answers. Some oils can be used, but others can’t.

In this blog post, we will discuss the two types of oils that can be used and the ones you should never try to put into your air compressor. You’ll also learn the motor oil composition, synthetic oil composition, and the appropriate viscosity of oil to use in air compressors.

What is Air Compressor Oil?

There are two types of standard compressor oil:

The first type of air compressor oil provides lubrication for all the parts in the pump and motor assembly. This can be referred to as a general-purpose oil, non-detergent oil, or straight mineral oil.

In compressors, general-purpose oils are typically used because they can handle both hot and cold climates without drastic changes in viscosity. These oils come in various thicknesses, from “light” to “extra heavy.”

Composition & Properties of Synthetic Air Compressor Oil

The compressor oil is a specific type of synthetic-based motor oil that doesn’t contain detergent. It’s used for lubricating parts in Screw Air Compressor units to keep the valves free of carbon build-up, increasing its service life and boosting efficiency.

Synthetic oils are Group III, Group IV, or a few products of a specific Group V base of oils. The synthetic oil molecules are soft and large enough to hold a high viscosity at a high temperature. Other benefits include an extra-long motor life & improved fuel economy.

Greater viscosity oils provide a coat that resists harsh weather conditions. These can offer superior protection for the accidental removal of oil deposits and reduce damage to the oil passageways of motor equipment. The manufacturer recommends using synthetic oils with 30-weight in hot areas.

The use of synthetic oils in an air compressor is possible if they are compatible. They can lubricate the different parts of your pump and motor assembly and handle high temperatures without breaking down as general-purpose oils can.

In addition, they can protect against heavy loads such as water, dust, and dirt that could contaminate other lubes used in the everyday oiling of pneumatic tools.

There are several types of synthetic oil. Each has slightly different chemical compositions to work best with particular tasks: their properties determine what temperature ranges and gas pressures they can handle.

What is Motor Oil?

Motor oil is a detergent-based oil that lubricates the parts. This oil is mostly used for vehicle engines, as it lubricates the machine because of constant friction. Friction causes wear and tear in pieces of the engine, and motor oil will reduce it.

Is it the Same as Engine Oil?

Based on their mixtures and additives, yes, both are referred to be the same. Motor oil and engine oil both help to protect and keep the engine lubricated. When the engine is well-lubricated, it helps to keep it working smoothly.

Composition of Motor Oil

Motor oil is a valuable resource for engine parts. It boosts performance, detergency, and corrosion-prevention abilities, which are helpful when you need to lubricate internal combustion engines, such as those in car or motorcycle engines.

Four-cycle (non-vehicle) Internal Combustion Engine oils are also available on the market; they work well with two-stroke engines.

The oil that lubricates your engine is not just for maintenance. Motor oils can be used as a varnish and dispersant to cool an overheated engine by reducing its respirometry from the moving parts or boosting seal integrity.

Can I Use Motor Oil in my Air Compressor?

Yes, you can use motor oil in your air compressor. It is the motor oil’s job to work well with different parts of an engine to handle high temperatures and low temperatures. However, not all types of motor oils are suitable for compressors since some contain chemicals or detergents that may damage them or can cause damage when mixed with other types.

If you have got a high-powered air compressor, then it would seem that pouring motor oil in will result in less than optimal performance. However, if the ideal fuel is used with these machines and appropriately matched to their weights and viscosities, they should work well together.

The best oil for an air compressor is non-detergent 20-weight or 30-weight motor oil. If you use lighter, thinner fluids in your machine, it will be less likely to fail and cause a disaster.

You should check your air compressor’s owner’s manual to determine what kind of oil will work for your device, as different air compressors require different types of lubricants.

What will happen to my Air Compressor If I Use Motor Oil?

Following our analysis of motor and synthetic oil, there are a few things you should keep in mind when using motor oil in an air compressor. Although motor oil can be used in air compressors, it may still cause problems.

These are some of the issues that can occur:

- When the detergents in your motor oil foam up, they make for a less than ideal lubricating experience. Your compressor will not function as well and could even seize if it gets too foamy.

- Some additives in motor oil can damage the air quality of your compressor, so it’s best not to use those.

- A high temperature can cause a buildup of carbon in motor oil.

So, make sure to go for non-detergent motor oil for your air compressor.

Synthetic Air Compressor Oil Vs. Motor Oil

Motor oil is mostly used in vehicles that provide lubrication to the car’s metal parts. It has additives and impurities that protect the engines of the vehicle. How? It prevents oil from wearing out in high temperatures (operating). This additive makes this motor oil bad for air compressors.

Synthetic oil is non-detergent oil, which is different from motor oil because it has detergents. This oil is specifically manufactured for the lubrication purpose of the air compressor (inside). Most manufacturers recommend this oil for air compressors instead of motor oil, reducing carbon deposits inside the compressor.

What can I substitute for compressor oil? Alternatives of Compressor Oil?

Hydraulic oil:

Because it has a variety of qualities, it is acceptable for air compressor oils. They perform best at low temperatures, have low viscosity, and do not oxidize in cold temperatures.

ATF:

It is an automatic transmission fluid commonly used in cars. The oil has some benefits that make it suitable for air compressors: it reduces wear and tear, cools down, and resists breakdown. It makes sure there is no shutdown because of overheating. But some can cause damage too.

Motor Oil: (Non-detergent)

Motor oil may not be recommended for frequent use, and use this option only in case of no other choice. They are manufactured with different processes that make them specific for some purposes, which do not include an air compressor.

In addition, you can use motor oil only in that case when it is non-detergent. The non-detergent will not have side effects and will be safe to use. But avoid frequent use!!

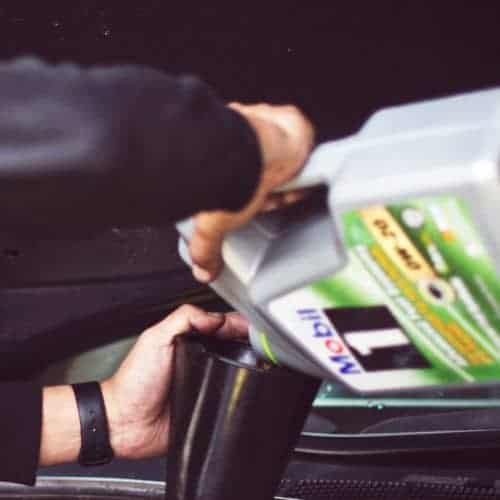

How to Change Air Compressor Oil?

For every compressor, the method of changing oil is different. In the case of an oil-lubricated unit, first, you need to empty the chamber and remove traces of old oil.

In the case of an air compressor, not cleaning it thoroughly can cause leakage issues. That happens because the vane/piston gets compressed, resulting in friction, which causes burns or melting. Make sure to clean it before refilling.

How Frequently Should You Change Air Compressor Oil?

How frequently should oil be changed? It depends on the condition of your air compressor. It is usually recommended to change the oil every 12-18 months. If you are using an oil-less type unit, there is no need to change the oil, but you can refill it.

How to Check Air Compressor Oil Levels?

Do you want to know how much oil is in your compressor? It’s not too difficult. First, locate the sight glass on either side of the air compressor, and look for a dot in the middle – that will be where all our oil resides.

In most of the models, you will find the sight glass at the base of the pump. If your oil level is above the dot, then you’ve poured the oil more than needed, and if it’s below the dot, then you should add some more.

The ideal condition is the center of the dot.

Right of Viscosity of Oil for Air Compressors

While putting motor oil in an air compressor, you need to consider the viscosity of your oil. You can’t just pick anyone you find on a shelf.

If you want to avoid having oil with detergents, please make sure that the oils are specified as non-detergent. In terms of viscosity, there’s a choice between SAE 30 and 20 air compressor fluids which will work for most compressors nowadays.

The best way is by specifying an oil without any additives in it. That includes dishwashing liquid or bleach because they’re often used as thinning agents when making motor lubricants.

However, most units can also handle lubricants with higher weights since their components are more robust than what we see inside cars and motorcycles; they can take more pressure without wearing out so quickly than smaller models.

Does Every Air Compressor Require Oil?

A large compressor (industrial) requires regular oil lubrication to the different parts to allow easy movements. Nowadays, some compressors are oil-free, but they are not exactly oil-free. Because they may not require oil in chambers, but their parts may need it

Oil-less Vs. Oil Lubricated Air Compressors

The main differences between oil-less and oil-lubricated compressors are the parts used to compress air. Air can be compressed using two types of mechanisms – piston mechanism or vane type mechanism.

Oil Lubricated Compressors:

Oil is injected into a cylindrical chamber, which has both rotating vanes on top and fixed pistons on the bottom side that work together to increase the pressure of the air inside it.

A smooth compression process is achieved using motor oil since less friction is created between moving components, resulting in more wear & tear. This method generates high temperatures, which leads to a short breakdown if not maintained regularly.

Oil-Less Air Compressors:

In this, there are no oil-lubricated parts which can mean reduced wear & tear and longer life. However, these compressors are tougher to start compared to oil-lubricated ones.

Due to the compression process, heat can accumulate inside the cylinders. In the absence of oil, overheating may occur very quickly, causing seals and other components to rupture, especially in older units that rarely receive maintenance.

Read More:

Oil-Free Air compressor Life Expectancy! 5 Ways to Enhance Lifespan

Conclusion

Can I use motor oil in my air compressor? Yes, it is motor oil’s job to work well with high-temperature and low-temperature engines. It boosts its performance, detergency, and corrosion prevention.

However, make sure you go for non-detergent motor oil while selecting oil for an air compressor because otherwise, it can cause foam and even damage the compressor. Some other substitutes other than motor oil are hydraulic oil and ATF.

Make sure to clean and remove the previous oil stains from the inside before refilling it. Also, the changing of oil should be done within 12-18 months and maintained regularly.

FAQs

Can I use diesel engine oil for the air compressor?

Using diesel engine oil for temporary use can be okay. But long-term use of diesel oil can lead to many issues in the compressor, which is quite harmful to the air compressor.

Can I use 5w30 in my air compressor?

Yes, you can use 5w30 in your air compressor, but it is not recommended because long-term use of these oils can destroy your compressors.

Can I use hydraulic oil in my air compressor?

Yes, you use hydraulic oil for the compressors because of its multiple qualities. But one of the best qualities is that it has a low viscosity, making it a great oil used in low-temperature areas, and low viscosity allows it to flow freely.

Can I use 10W30 in my air compressor?

Is 10W30 recommended for air compressors? No, it’s best not to use 10W30 in your air compressor. Also, the weight and viscosity will not meet the needs. 10W30 have detergents, and the manufacturers of air compressors advise using air compressor oil without detergents.

Read in Detail: Can I Use 10w30 in My Air Compressor?

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.